Spice Route Legal

India’s Green Hydrogen Certification Scheme: Building Trust for a Cleaner Tomorrow

The global emphasis on clean and sustainable energy is intensifying, with green hydrogen emerging as pivotal in the drive for decarbonisation. In this dynamic landscape, India has marked a significant milestone through the launch of its Green Hydrogen Certification Scheme (“Scheme”).

The National Green Hydrogen Mission (“Mission”) was introduced in January 2023, which established a core framework for the green hydrogen sector in India. In August 2023, the Ministry of New and Renewable Energy (“MNRE”) introduced the Green Hydrogen Standards (“Standards”), which define green hydrogen as hydrogen produced using renewable energy, including production through electrolysis or conversion of biomass. The Standards also identify a “well to gate” emission threshold of 2 kg CO₂ equivalent per kilogram of hydrogen, averaged over a 12 (twelve) month period for emissions generated from water treatment, electrolysis, gas purification, drying, and compression of hydrogen (“Threshold”) during the production of green hydrogen.1 The Standards refer to a separate framework to be rolled out by MNRE for measurement, reporting, monitoring, on-site verification, and certification of green hydrogen and its derivatives.

On 29 April 2025, MNRE launched the Scheme with the aim of providing a structured approach to certifying hydrogen as “green” and to enhance transparency and credibility in the production of hydrogen sourced from renewable energy, facilitating the development of a green hydrogen market in India. The certification of hydrogen as “green” under the Scheme is primarily determined by the intensity of greenhouse gas (“GHG”) emissions generated during its production. This emissions profile forms the foundation for establishing a reliable and comprehensive certification framework. Accordingly, the Scheme sets up a monitoring, reporting, and verifying (“MRV”) framework for the calculation of GHG emissions at every stage of hydrogen production to ensure that the Standards are being followed. It puts in place a clear structure that outlines the roles of different stakeholders, such as project developers, verification agencies, and government authorities.

Applicability and Scope of the Scheme

The Scheme takes a holistic approach, encompassing every step of the project’s value chain, from production to compression, purification, and on-site storage. However, the processes that go beyond the project’s established boundaries, such as transportation, off-site storage, conversion into derivative carriers, reconversion procedures, and end-use applications, are expressly excluded from the Scheme’s purview. These exclusions make it clear that the Scheme’s main objective is to strictly validate and certify the green attributes of hydrogen at the point of production.

Under the Scheme, obtaining a Green Hydrogen Certificate is mandatory for green hydrogen facilities or producers who:

- Receive any incentives or subsidies under the Strategic Interventions for Green Hydrogen Transition Programme from the Central or State Government for green hydrogen production;

- Intend to sell or utilise green hydrogen within India;

- Avail any governmental exemptions or concessions; or

- Supply a portion of its output to domestic off-takers while exporting the remainder.

Exemption from the purview of the Scheme

The Scheme provides for an exemption for certification for producers whose facilities have an annual production capacity of 10 tonnes or less; however, such facilities may voluntarily apply for the certification. Additionally, producers whose entire green hydrogen output is designated for export and do not avail any governmental benefits, such as incentives or concessions, are exempt from obtaining the certification.

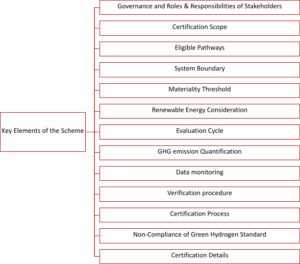

Key Elements of the Scheme

What Makes Hydrogen “Green”?

Production of hydrogen to qualify as “green” under the Scheme must be produced using either electrolysis or biomass conversion, and the GHG emissions arising from water treatment, electrolysis, gas purification, drying, and compression of hydrogen should be within the Threshold. Producers also have the ability to propose new pathways for eligibility under the Scheme to MNRE, and the technical committee is empowered to determine their inclusion under the Scheme.

Additionally, the Scheme requires mandatory use of renewable electricity in production. The electricity from renewable energy sources must be physically traceable. Producers can either directly procure renewable energy or use energy banking, where the renewable energy used is matched to the quantity of hydrogen produced.

Producers must have valid power purchase agreements with renewable energy suppliers, ensuring that electricity consumed is from renewable sources. If non-renewable energy is used during the operation of the green hydrogen facility, the consequent GHG emissions from that energy will be included in the overall emissions intensity calculation.

The Scheme does not allow the use of carbon offsets or renewable energy certificates to meet renewable energy utilisation requirements; however, energy procured through the green tariff mechanism2 and power exchanges3 (such as through Green Day Ahead Market) will be considered as renewable energy.

Governance, Roles, and Responsibilities of Stakeholders

The governance of the Scheme is led by MNRE, which is responsible for overseeing its implementation. An Implementing Agency (“IA”) will be appointed to carry out the Scheme, with the technical committee providing strategic direction and issuing green hydrogen certificates. The IA checks compliance based on reports from the Accredited Carbon Verification (“ACV”) agency, which verifies the production process. The IA manages the Scheme’s operations, while MNRE provides policy guidance and coordinates with stakeholders.

Green hydrogen producers must follow the requirements on reporting, calculating, monitoring, verification of emissions, and undergo annual or regular checks by the ACV agency. They must also register on the Green Hydrogen Certification Portal (“GHCP”). The ACV agency verifies compliance and sends detailed reports to the IA.

Emission Accounting and GHG Quantification

1. System Boundary

The system boundary under the Scheme4 for hydrogen production projects covers all direct emissions from the production process and indirect emissions from the electricity or fuel used. Emissions from water treatment, electrolysis, purification, drying, compression, and storage will be covered for electrolysis-based hydrogen production. Emissions from biomass processing and conversion are accounted for in biomass-based production. Additionally, emissions from onsite water treatment and input materials such as water and oxygen are included. Emissions related to construction and renewable electricity generation are excluded from the system boundary. The final hydrogen composition and pressure must be documented on the certificate.

2. Emission Calculations

The Scheme requires evaluation of emission intensity calculations to be conducted every financial year, and the period of evaluation cannot exceed more than 12 (twelve) months. The evaluation cycle will begin from the date of commencement of operations in the first year of operations.

Producers are required to calculate estimated GHG emissions and emission intensity using the calculation methodology under the Scheme. If the methodology does not cover guidance on an aspect, then the relevant ISO standards, such as ISO 14064-1,2, and 3, will be applicable. Emissions must be rounded to one decimal place.

An emission source will be considered immaterial under the Scheme if it contributes less than 1% of the Threshold, and collectively, all immaterial sources account for less than 5% of the Threshold with regard to the system boundaries. However, if an emission source is within the 1% Threshold but its exclusion would cause the total excluded emissions to exceed 5% of the Threshold, that source would be treated as material and included in the emission intensity calculation under the Scheme. Similar emission sources are to be categorised together and considered to avoid multiple claims for exclusion, which, when aggregated, may exceed the Threshold.

3. Emission Monitoring

A monitoring plan that outlines how emissions will be tracked, including the sources, data collection methods, and calibration of instruments, should also be adopted by producers. The calculation also accounts for transmission losses from non-renewable electricity and emissions from co-products based on energy content. If external heat is used, emissions from any additional fuel burned will be included. The final certificate will show the total carbon footprint of the hydrogen produced.

Monitoring and Verification for Green Hydrogen Production

Green hydrogen producers must keep detailed records of production, including sales to the first buyer, for at least 5 (five) evaluation cycles or from the date of commencement of operations if the facility is less than 5 (five) years. These records should be as per the green hydrogen MRV framework. The records will be verified by an ACV agency to assess the environmental impact and resource use of hydrogen production.

Producers aiming to claim “green” hydrogen credentials in the following financial year must engage an ACV agency by 31st March for the evaluation cycle for verification and compliance with the Scheme. Producers must also track daily production, including its physical and chemical properties, and energy consumption (fuel, electricity, water, and feedstock). While transparency is important, sensitive commercial information, such as offtake contracts, is not required for the certification. The agency will submit a verification report through the GHCP.

Types of Certificates under the Scheme

The Scheme provides four main types of certifications that validate different stages of the hydrogen production facility and the hydrogen produced :

- Concept Certificate: This is a voluntary certification that confirms a hydrogen production facility’s design complies with the Scheme’s requirements. It becomes applicable once the facility’s design or Front-End Engineering Design (FEED) is approved. The certificate verifies that the proposed design aligns with the MRV framework verified by the ACV agency and as outlined in the Scheme. Although not mandatory, it allows project developers to demonstrate early-stage compliance, which can help secure funding, regulatory approvals, or investor confidence.

- Facility-Level Certificate: This certificate is mandatory for facilities that wish to obtain further certifications. It confirms that the facility complies with all MRV requirements and has obtained all necessary statutory approvals, including the “consent to operate.” The facility-level certificate acts as a foundational compliance step before procuring certification of the hydrogen produced.

- Provisional Certificate: This certificate is obtained on a voluntary basis and is automatically generated based on the production data submitted. It is available for production durations between 1 (one) and 11 (eleven) months and is useful for producers who wish to track and demonstrate compliance on an ongoing basis. In the event the ‘facility level certificate’ is secured post commencement of operations, the initial provisional certificate shall be deemed effective from the date on which the “consent to operate” is received and shall remain valid up to the conclusion of that calendar month. While it does not replace the final certificate, it can serve as a useful interim record for internal or stakeholder reporting.

- Final Certificate: This is compulsory for facilities availing government subsidies, exemption, or selling or using green hydrogen within India, or catering to both domestic and export markets, and includes a unique identification for every 100 kg of hydrogen produced. It also records the project details, the year of production, and the emission intensity. The final certification serves as conclusive proof of the hydrogen produced as “green” under the parameters and standards outlined in the Scheme and can be utilised for claiming carbon credit under the Carbon Credit Trading Scheme, subject to additional requirements.

Non-Compliance with Green Hydrogen Standards

MNRE or its designated agency reserves the right to revoke certifications if a provisional certificate is issued for a specific evaluation period, but the final verified emissions exceed the set threshold or if a producer who has received a provisional certificate fails to submit an application for the final certificate within the stipulated timeframe.

To accommodate delays, MNRE allows a 1 (one) month extension for final certification applications, provided the producer pays a late fee equivalent to the certification charge. The deadline for submitting this application is 31st July of the following evaluation cycle. If submitted on time and without discrepancies, the certificate is expected to be issued by 31st August. If any concerns exist, the producer will be asked to provide clarifications by 31st August and resubmit by 30th September. Following a second review, the certificate may be issued by 31st October. If concerns persist, the data may be verified by another authorised agency, although the final decision lies with the technical committee.

On the first instance of non-compliance, the provisional certificate for that cycle will be revoked. If a second instance occurs within three years, the producer will be barred from applying for a provisional certificate during the next evaluation cycle, and any existing provisional certificate will be cancelled. Occurrence of repeated non-compliances may result in stricter penalties, including temporary disqualification from the certification process. Such temporary disqualifications will be formalised through a separate executive order issued by MNRE.

Conclusion

The Scheme marks a promising step towards establishing a green hydrogen ecosystem. By setting stringent emissions caps and requiring the use of physically traceable renewable electricity, India positions itself as a leader in the global green hydrogen production race. The requirement for independent verification and transparency in emissions calculations also provides a reliable framework for producers and stakeholders.

While the Scheme presents a strong foundation, there are aspects where further refinement could enhance its comprehensiveness. For example, the certification timelines, although essential for maintaining momentum, could benefit from a degree of flexibility to accommodate unforeseen complexities in the certification process. Additionally, the exclusion of certain emissions sources, such as those linked to construction and infrastructure development, might result in an incomplete picture of the project’s full environmental impact. While the Scheme does an excellent job of covering the direct and operational aspects of hydrogen production, it does not fully account for emissions arising downstream, which could influence the overall carbon footprint. Addressing these areas could further strengthen the Scheme’s environmental integrity and make it a more holistic model for sustainable green hydrogen production.

Despite these challenges, the Scheme provides a solid foundation for future growth and innovation in the green hydrogen sector. By setting clear guidelines and rigorous environmental standards, it offers a framework that can inspire investor confidence and encourage sustainable practices. With continuous refinement and input from industry stakeholders, this initiative has the potential to evolve into a global benchmark, playing a crucial role in accelerating the transition to a low-carbon hydrogen economy.

[1] https://www.pib.gov.in/PressReleasePage.aspx?PRID=1950421

[2] The Green Tariff mechanism enables consumers to purchase a designated quantity of electricity from the distribution licensee at a premium rate, with the assurance that the procured power is sourced exclusively from renewable energy (RE) sources and appropriately certified as such.

[3] Power Exchange mechanism enables consumers to place a bid for green power, pursuant to which the bids and offers from RE producers are matched.

[4] “System boundary” means processes for Green Hydrogen production which are covered in the GHG emission intensity calculation.

This website is owned and operated by Spice Route Legal, and is exclusively meant to be a source of information on the firm, it’s practice areas, and its members.

It is not intended and should not be construed as any form of advertisement, solicitation, invitation or inducement of any sort from the firm or its members.

Spice Route Legal does not warrant that any information provided on the website is accurate, complete or updated, and further denies liability for any and all loss or damage caused to the user as a result of their reliance on the content provided.

The information made available on this site must in no way be relied upon, or construed, as legal advice. If you need legal assistance, we recommend you seek help from competent counsel licensed to practice and advise in the relevant jurisdiction.